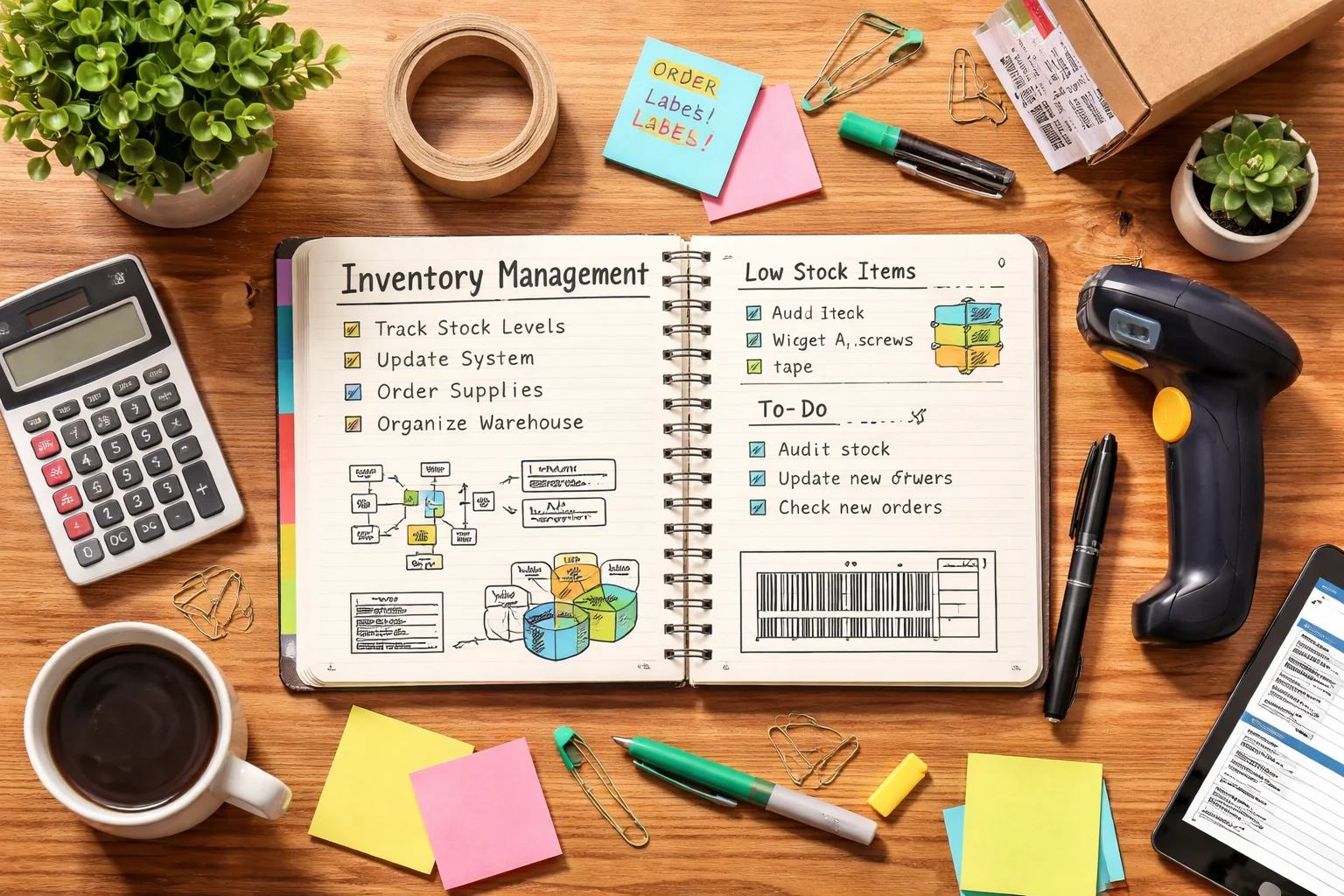

Smart Inventory Management Best Practices for Thriving Businesses

So here’s something that’ll make you groan—ever run out of your most popular menu item on a wildly busy night, and realize too late you’d totally spaced on reordering? Don’t even get me started about accidental double orders (hello, the tuna situation of 2022). Well, inventory management best practices exist to keep you from getting into all those sticky messes. This is for anyone who’s ever lost sleep worrying about their stock, or who just wants their kitchen—or, hey, any business—running smoother than a gravy boat on Thanksgiving.

What is Inventory Management?

Alright, in the simplest terms: Inventory management is just keeping tabs on what you’ve got, what you need, and when to get more. Not rocket science. Yet, boy, does it trip folks up.

- Basically, it’s knowing what’s on your shelf at all times.

- Means not over-ordering or, the opposite, running out mid-service.

- Good inventory management helps you save money and (even more important) your sanity.

- Trust me, it’s the unsung hero behind the scenes of every thriving business.

“Since we started tracking our inventory better, our waste dropped by half—and stress levels plummeted, too!” — Local bakery owner

Inventory Management Best Practices for Maximized Efficiency

Here’s the stuff I wish I’d learned way sooner. Some seems obvious—till you forget and wind up with 100 pounds of onions.

- Track inventory daily. A quick check every day beats a big, stressful audit once a month.

- Use software, not just your head or a paper list. Honestly—let technology do its thing, even if you love lists as much as I do.

- Set minimum stock levels (the fancy phrase is “par levels”) so you reorder before it’s too late. Yup, works for flour and napkins.

- Rotate your stuff—first in, first out. Don’t let last week’s lettuce turn into green mush in the back. Ew.

“We thought we didn’t need a fancy system, but with even a basic app, mistakes dropped fast. Now we always have what we need.” – Restaurant manager

Achieving Inventory Optimization through Strategic Supplier Relations

This sounds… well, like “business speak,” but it’s dead simple: be pals with your suppliers.

- Talk to them regularly—good relationships save you when you’re in a pinch.

- Negotiate better deals if you’re buying lots of something. Bulk = discounts (usually!).

- Keep a backup supplier for essentials. Because no one wants to explain to a customer that your award-winning burger is off the menu.

“When our cheese supplier had delivery issues, our backup stepped up. It saved our event—and our reputation.” – Deli owner

The Inventory Management Process

It’s basically a cycle. Not hard, but easy to skip steps if you’re busy.

- Receive and safely store all products (or they grow legs and wander).

- Check what you’re using and what’s moving slow. Make a list that’s better than just ‘chicken? maybe?’

- Reorder before you hit zero. Seriously, write reminders if you’re forgetful like me.

“Getting everyone on the same process kept us out of so many jams. Fewer surprises, more happy customers.” – Cafe owner

10 Inventory Management KPIs That Actually Matter

KPIs just means “what numbers should I care about?” (‘Cause not everyone loves spreadsheets.)

- How fast you sell certain products (turnover rate)

- How much you’ve got—too much or too little (stock on hand)

- How long stuff sits before it’s sold (days of inventory)

- Gross profit margin—are you making money or just looking busy?

- Frequency of stockouts (nothin’ worse than running out)

- How much stuff you throw away (waste or spoilage)

- Time between orders and getting the goods (lead time)

- Accuracy—are your records actually correct?

- Supplier performance (do they flake or deliver on time?)

- Overall cost of managing all your inventory (shouldn’t give you heartburn)

Common Questions

How often should I count my inventory?

Honestly, more often is better. Even just a quick check each morning can save you headaches later.

What’s the easiest way to avoid waste?

First-in, first-out. Use the oldest stuff first, and label it with big neon tape if you have to.

Is there really a big difference between paper lists and software?

Yep! Once I switched to an app, my errors dropped like a bad soufflé. Even cheap software beats scribbles.

Do I need more than one supplier?

If you rely on something crucial, having a backup isn’t just smart—it’s a lifesaver.

Can you overdo inventory tracking?

I mean, sure—don’t spend more time counting than selling, but don’t avoid it, either. Balance!

Wrapping Up: Inventory Know-How Makes Life Easier

Alright, so keeping your chill in the kitchen (or shop, or wherever) is mostly about nailing these inventory management best practices. Use some kind of system. Rotate your items. Get on good terms with your suppliers (bring ‘em cookies—okay, maybe not, but you get my drift). Check your progress every so often using stuff like turnover and waste. If you need a little more detail, check out this Complete Guide to Inventory Management: Types, Efficiency and More or dive into Inventory Control Defined: Best Practices, Systems, & Management. And for a quick rundown, you can’t go wrong with 6 Inventory Management Best Practices – Wasp Barcode Technologies. Don’t let the process scare you—it’s like tweaking a great recipe. It gets easier with practice!