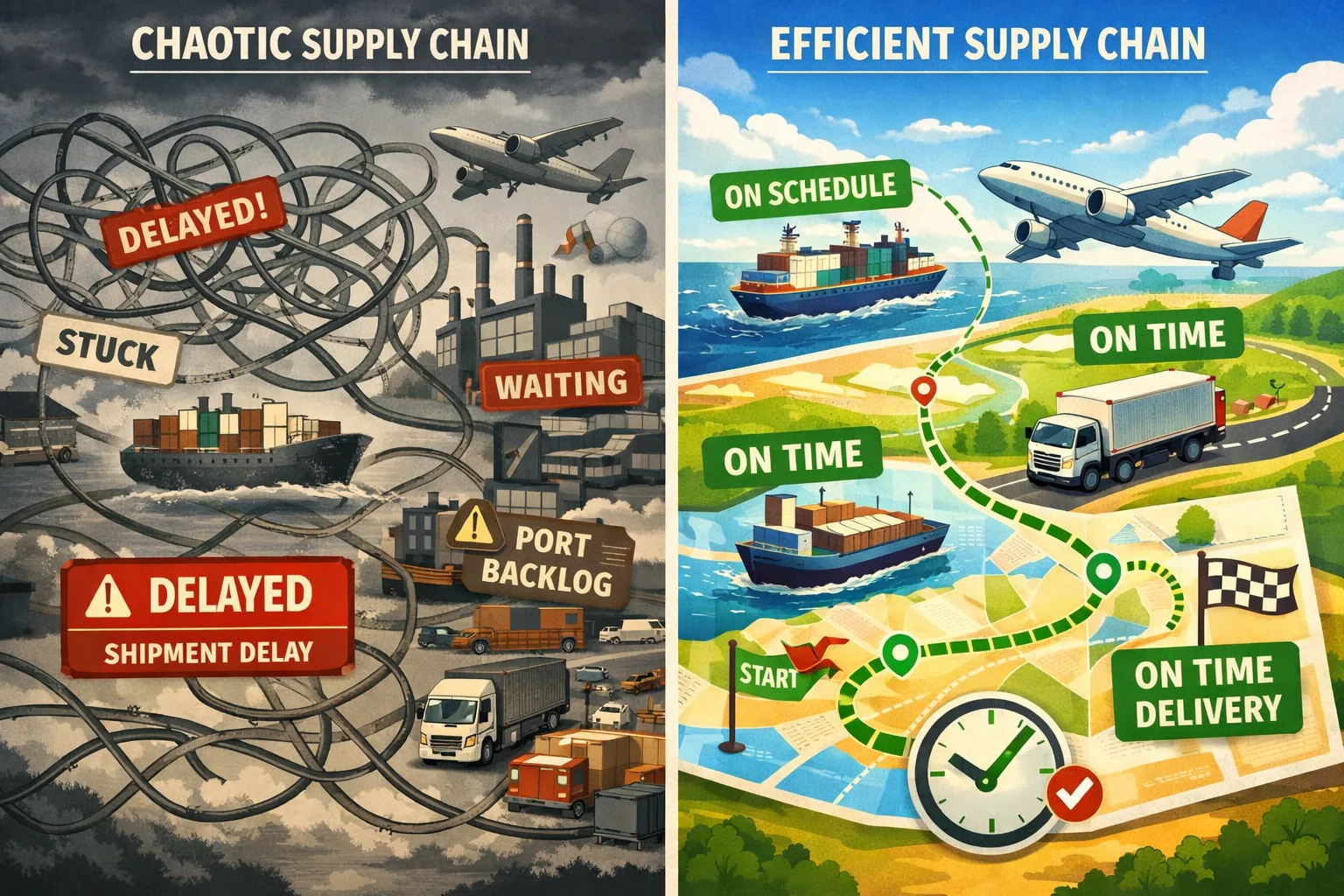

Tackling Common Supply Chain Problems and Solutions You Need to Know

Let me tell you—common supply chain problems and solutions are basically the unsung “recipe” of every restaurant and food blogger’s world. Seriously, I don’t care if you’re running a little taco shack on a corner or a five-star restaurant with gold-flecked dessert, if your tomatoes don’t make it on time (or worse, they arrive all mushy), your whole plan falls apart. Ever had to serve BLTs with wilted lettuce? Nightmare city. But hey, I’m here to make things less scary—and way less complicated.

So, let’s dig through the kitchen pantry of supply chains together, and see how to dodge those classic mishaps that pop up when moving stuff from Point A to Point B (or, well, all the way to Z some days). Stick with me and I’ll show you fixes that don’t involve spreadsheets thicker than your grandma’s holiday fudge.

What is supply chain management?

Basically, it’s the behind-the-scenes magic (or, let’s be honest—sometimes the chaos) of getting your ingredients from farm to table, store to home, whatever.

- It includes sourcing, moving, storing, and delivering everything.

- Good management means fewer angry calls from customers or kitchen meltdowns. Huge win.

- Mess this up and you’ll notice quickly—stuff either runs out, doesn’t show, or costs a fortune for nothing.

- Not just big companies. Even your local bakery deals with this, just on a smaller scale.

A real friend of mine runs a little pie shop—when her flour got stuck in a warehouse across state lines during a snowstorm? No pies, unhappy town.

Common supply chain issues and corresponding solutions

Okay, picture this: orders late, quality dives, costs spike. Seen it happen way too often. But here’s what actually helps:

- Late deliveries: Build in buffer days. Don’t believe anyone who promises magic shipping every single time.

- Stockouts or overstocking: Use inventory tracking apps; even a spreadsheet beats sticky notes. Trust me, I’ve tried the sticky notes.

- Communication breakdowns: Make your people text, call, or email (or all three). Silence is never golden here.

- Quality drops: Don’t be afraid to send stuff back or switch suppliers if you get junk.

“We were losing sleep over late cheese deliveries, but switching suppliers and adding group texts saved our bacon (and topped our pizzas),” – Dina, local pizzeria owner.

10 Ways to streamline your supply chain

Let’s be real, nobody wants a complicated solution for a simple problem. So—here’s my quick “mise en place” list for smoother sailing:

- Track everything (just… don’t rely solely on memory).

- Set true reorder points—guesswork is not your friend.

- Build honest relationships with your suppliers—the good ones save you more than coupons do.

- Automate whatever you can (alerts, reorders, even just reminders).

- Don’t ignore small hiccups; they add up fast.

- Review costs regularly—weekly, not yearly.

- Train folks to spot problems early. A sharp-eyed staff is gold.

- Use local suppliers if you can. Less travel, less trouble.

- Have plan B, C, even D (yeah, it’s work upfront, but you’ll thank me).

- Celebrate when things do go right—good vibes improve everything.

I’ve seen kitchens turn around in a month with just 3 of these. Don’t be afraid to start small!

How to measure supply chain performance: 7 Tips

Too many people just “feel” like their system is working, but it’s kind of like guessing salt in a sauce—dangerous. Here’s how you can tell for real:

- Set clear goals (faster delivery, less spoilage, etc.).

- Check your order accuracy. If half your shipments are wrong… yikes.

- Measure how long stuff sits around (storage costs sneak up on you).

- Track delivery times—don’t just hope they’re speedy.

- Ask customers if they’re happy! Don’t wait for complaints.

- Count returns or waste—that’s money out the door.

- Review problems every month. Sounds boring, but think of it as a safety net.

If you do these even a little, you’re way ahead of most. I’m telling you—people skip #5 and it always backfires.

The current state of the global supply chain

Straight talk: things are… weird right now. The world’s still a little scrambled from the last few years.

- Products are moving, but delays are the new normal. Patience is key.

- Prices? Up and down like a bouncing ball. Plan for wiggle room in your budget.

- Some items just aren’t available like they used to be. Time to get creative (or swap brands).

- You can still make things work—just expect to pivot. A lot.

If you hear a restaurant say something isn’t available “today,” guarantee it’s a supply chain hiccup. We’ve all been there!

Common Questions

How do I pick the best suppliers?

Ask around. Try samples. Trust your gut—if someone seems shady or slow out the gate, it only gets worse.

Is tech worth the hassle for small businesses?

Absolutely. Even simple tracking apps save headaches. You don’t need a tech wizard—just dabble a bit.

How often should I check my inventory?

At least once a week—even more if things move fast. Better too often than not enough.

Can small businesses survive big supply chain problems?

Yes! It just takes flexibility, asking for help, and not panicking. Keep your options wide open.

Are local suppliers always better?

Not always, but you get faster support and fresher stuff. Worth checking!

Ready to solve your kitchen headaches for good?

That’s everything I wish someone had told me when I started juggling onions and email chains. Supply chains will never be stress-free, but with a little planning (and a lot less perfectionism), you can keep things rolling—even if the world throws you flaming curveballs. Check in with reputable guides on new fixes—like 10 Supply Chain Management Problems With New Solutions, browse 15 Key Supply Chain Challenges to Overcome, or see what others are facing at Top 10 Supply Chain Problems to Overcome. Remember, you’ve got this—swap stories, share tips, and keep your kitchen humming.